At LKHPD, we provide customised flexible links that

- Absorbs vibrations caused by operations and movements inside machines

- Protects against movements and expansions in machines and equipment

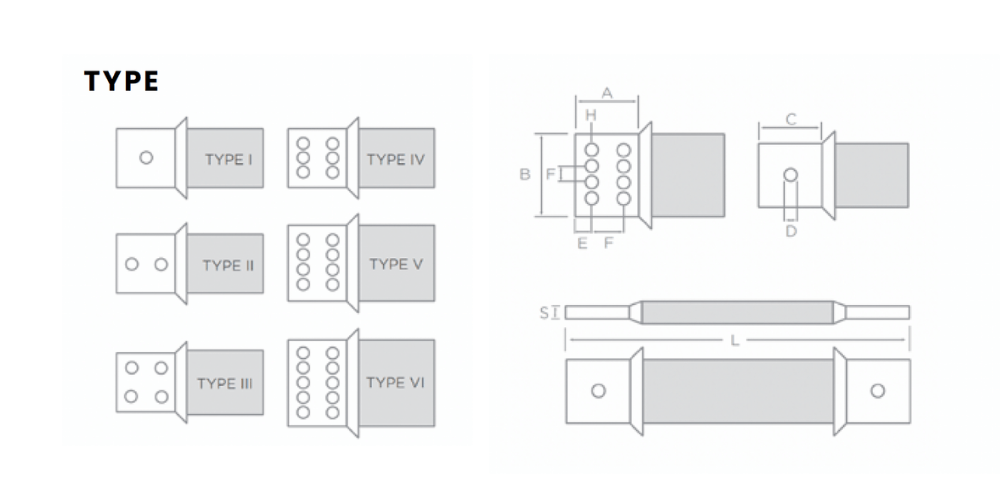

Standard flexible dimensions: L = 300 F = 50 E = 25

While enquiring please specify

Besides flexibles can also be fabricated as per your design, size and specifications.

Highly flexible connectors are manufactured by braided tapes with bare, tin or silvercoated copper wires diameter of 0.10/0.20 mm. Standard flexibles are non-insulated but on request, it is possible to deliver the connectors with insulation tubes. Standard lengths are 300 mm and drilling patterns are specified, however, the designs lengths and drilling patterns are changeable to suit your fitment. The contact areas are assembled with solderless pressed bare copper connectors which on request are tin or silver coated.

The advantage of the solderless pressing process is that only material of same analysis and same conductivity is being connected which is not the case where tin or welding is additionally used.

Standard manufactured connectors have a width of 20-300mm. Possible crosssections are 25-6000 sq mm or above.

Flexible connectors are manufactured of Copper or Aluminium strips. They consist of several stacked strips riveted or welded at contact areas having a constant cross-section over the whole length. Busbars and laminated connectors with the same cross-section can be loaded with the same current. Laminated connectors are utilised as flexible expansion connectors in order to connect busbars of switch gears, transformers, generators, etc. Due to their elasticity, thermal expansion of busbars is being compensated. Most of the parts are being used as expansion connectors to prevent damages caused by vibration at switch gear operations.

Another area of applications is inside parts of machinery (e.g. welding machines, transformers) or switch gears as flexible components. These kind of connectors have to realise movement inside machines and switch gears. We have different methods of production, to manufacture suitable connectors for the variable applications.

Hence, we are able to provide connectors in